Temperature Regulating Fabric – Outlast® Temperature Regulation reduces sweat production

Outlast is a specialist in proactive heat management for textile materials. The Heidenheim company uses a technology originally developed by NASA. The temperature regulating fabrics can be used in many different areas and products to add value in functionality and comfort for the customers – by using natural wax and the laws of physics.

Up to 48% less sweating thanks to Outlast®* temperature regulating fabrics

Microencapsulated natural wax can be applied to almost any textile material thanks to various procedures developed by Outlast. These capsules can capture and store body heat, forming a natural heat buffer. Overheating and the start of sweat production can thus be efficiently avoided. Conventional heat management systems try to channel the sweat that develops and wick it away from the body.

Outlast® temperature regulating materials start working even before the moisture is created. In this way, the amount of sweat can be significantly reduced. Independent studies confirm a reduction of up to 48%*. And the highlight: If the body temperature falls again, for example due to reduced physical activity, the natural wax in the temperature regulating material clothing releases the stored heat again. Despite fluctuating external temperatures, the user can thus always enjoy a wonderfully balanced climate.

* Tests for various final applications such as clothing, shoes, and helmets conducted by C. Russ – INSIDE CLIMATE, an independent test laboratory in Munich (THG AreaView – SleepView). Details on request.

Feel the Outlast® difference! A small selection of the advantages of temperature regulating fabric:

- Better sleep: A balanced temperature promotes deeper sleeping behavior

- In shoes: Less blister formation and odor development due to reduced moisture

- For athletes: Reduced energy consumption and an excellent fluid balance thanks to reduced sweating

- More comfort for all kinds of textiles (“feel-good clothing”)

- Better concentration and higher performance in all textile areas of occupational health and safety

- Improved functionality in all orthopedic “next to skin” products

- In leisure: By wearing functional clothing equipped with Outlast®, the risk of a cold is significantly reduced when hiking, gardening, or during any other leisure activity

“Even after over ten years at Outlast, I still love the ‘wow effect’ when customers feel the ‘Outlast® difference’ for the first time by touching our products.”

Dirk Keunen, Sales Director

The big picture at a glance

The company, originally founded in the USA, is now managed from Germany. The majority of the Outlast value creation chain also takes place in Germany and other European countries and in the USA. For instance, the AERSULATE® materials and our products for the bedding industry are predominantly “Made in Germany”. Sustainability, quality, customer service, and innovation are unshakable pillars of the Outlast philosophy.

Find out more about Outlast, our philosophy and the sustainability of our temperature regulating fabrics.

Tailored to your needs

We will be happy to provide you with individual, no-obligation advice. Create the basis for tomorrow’s success today and contact us!

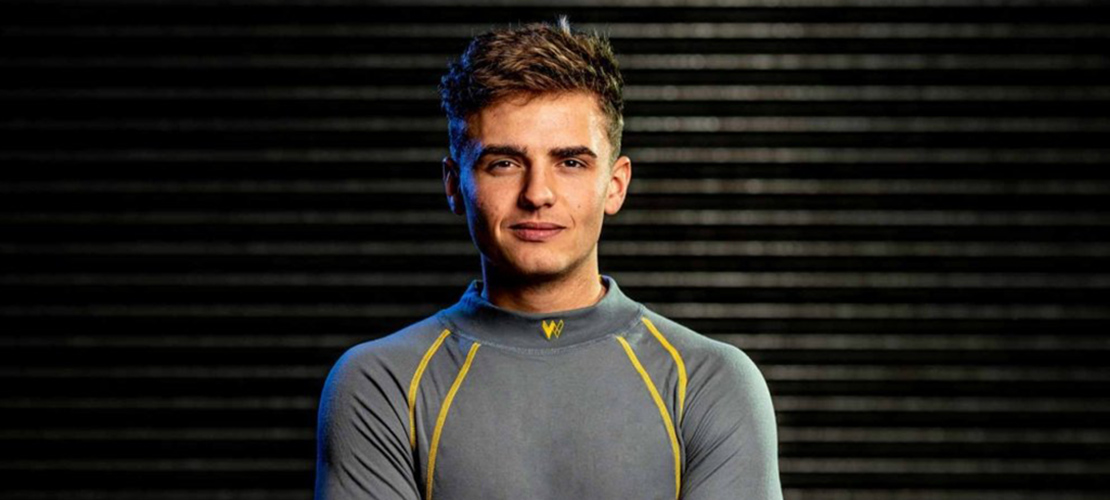

Case study: Walero racing underwear

I founded Walero in 2014 to find a solution to the problem of racing drivers constantly overheating. I race myself and know what it’s like to battle against the extreme temperatures (often far over 50°C [122°F]) in the cockpit while you are fighting for victory at high speed just a few centimeters away from other drivers. At the same time, you’re encompassed by protective equipment such as a Nomex racing suit, a base layer, and a helmet, and you are firmly strapped into a racing seat. Needless to say, heat stress represents a major problem and impairs cognitive function, reaction time, and condition.

I wanted a solution that is part of our everyday equipment instead of having to use heavy and expensive air conditioning systems that could cost you a loss of speed from tapping into the power. Racing drivers must wear extensive PPE due to the risk of fire. Outlast offers the perfect solution: We were able to combine the Outlast® Temperature Regulation with the outstanding flame retardant called Protal to make a high-performance, technically impressive woven fabric that is both entrancingly soft and comfortable.

This resulted in an excellent technical solution that allowed us to successfully enter the motorsport market. The performance advantages that we achieve by using the Outlast® Temperature Regulation in our clothing helped us quickly begin to sell around the world.

These benefits were confirmed in tests that we performed at Cranfield University. The tests showed a significant reduction in heart rate, breathing, and core temperature as well as a massive reduction in sweat by 40% compared to another standard Nomex base layer for motorsport. What is good for space is also good for motorsport!

We intend to expand the use of Outlast® Temperature Regulation to other markets and are looking forward to the future.

Fiona James, Founder & CEO, Walero Ltd, UK