Innovative NASA Technology

Aersulate® sets new standards in insulation

We have developed a groundbreaking technology that enables the direct integration of the extremely lightweight and insulating material, aerogel, into viscose fibers. This innovation significantly enhances insulation performance without adding extra weight. For example, in the bedding sector, warm winter blankets can now be produced with the same lightness as summer blankets. Similarly, ultra-light jackets, ski pants, work wear and other garments can deliver exceptional insulation performance.

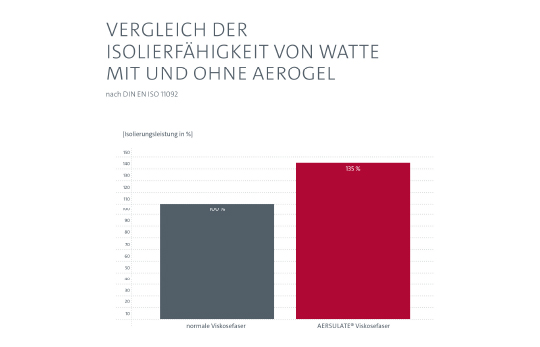

Initial tests conducted by an independent institute confirm that fibers optimized with Aersulate provide up to 35% higher insulation performance compared to conventional viscose fibers. This is achieved thanks to an impressively high aerogel volume content of 50%.

Aersulate® Fibers Enhance Sleep Comfort

Ideal bedding strikes a balance between properties that often seem contradictory: it should feel lightweight on the skin while providing cozy warmth, without causing excessive sweating. Overly heavy blankets can feel uncomfortable and restrict breathability, while overly light options often fail to insulate effectively.

Until now, manufacturers faced the challenge of compromising between weight and insulation performance. However, our development team has achieved a breakthrough by successfully integrating the challenging-to-process material aerogel directly into fibers using a patent-pending process. This innovative method resolves the long-standing dilemma, paving the way for bedding that is both lightweight and exceptionally efficient at insulation.

Lightweight, Sustainable, and High-Performance – Ideal for the Apparel Industry

Our batting with an exceptionally high aerogel content makes end products noticeably lighter without compromising performance. This is particularly valuable for premium sportswear, such as jackets, ski pants, work wear and similar products, where lightness can be a decisive purchasing factor.

The technology also stands out for its sustainability: the highly insulating aerogel is derived from sand, while the fibers are made from wood-based viscose material – an eco-friendly and sustainable alternative. Aersulate® fibers deliver excellent thermal protection without relying on down, contributing to animal welfare. The highlight: Even under pressure, such as in the knee and elbow areas or from backpack straps, the fibers retain their high performance, ensuring reliable insulation in all circumstances.

Exceptional Insulation Performance Thanks to Aerogel

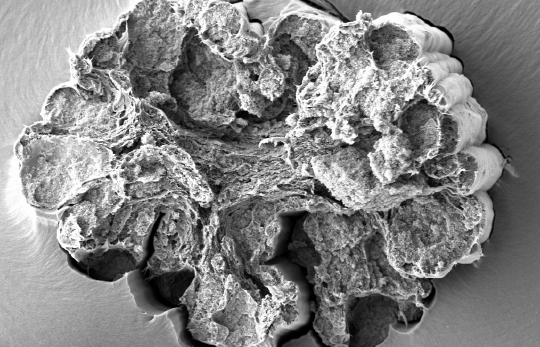

Aersulate® fibers contain an Aerogel volume fraction of 50%. But what does that mean? Aerogel is a silica-based solid derived from quartz sand, renowned for its unparalleled insulating properties. Its extraordinary performance is due to its highly porous structure, which is composed of 98% air – the ideal material for insulation. These unique characteristics have made Aerogel an essential material for NASA's space missions for many years. Unlike conventional insulating materials such as foams, wadding, or non-woven, which rely on trapped air for thermal regulation, Aerogel captures air within its fiber structure. This allows it to maintain its insulation capabilities even under pressure and/or exposure to moisture. This represents a significant advantage over traditional materials, which tend to lose their effectiveness under such conditions.

Facts about Aersulate® Fibers

- Contain Aerogel – the lightest solid in the world.

- Aerogel is a silica-based material derived from quartz sand, renowned for its outstanding insulation properties.

- NASA-Approved – Aerogel is utilized by NASA in space missions.

- High Air Content – The fibers’ high aerogel content by volume ensures exceptional insulation.

- Performance Under Pressure – Insulation remains highly effective even under pressure.

- Animal-Friendly – A sustainable alternative to down.

- Sustainable Material – Made from viscose, promoting eco-friendliness.

- Patent-Pending Innovation – A pioneering solution in insulation technology.

35% Lighter with Exceptional Performance

An independent, ISO-certified laboratory rigorously tested the insulation performance of Aersulate® technology. The study compared 2 cm-thick viscose wadding with and without aerogel content, following DIN EN ISO 11092 standards.

The findings demonstrated that Aersulate-optimized wadding delivers an impressive 35% improvement in insulation performance compared to conventional viscose fibers. This breakthrough allows bedding and jacket fillings to be up to 35% lighter while maintaining outstanding thermal efficiency.

"With this groundbreaking technology, we successfully use the full benefits of aerogel for the textile industry, without compromising on softness or comfort. Manufacturers in the apparel and bedding sectors can now create exceptionally lightweight yet highly insulating products that meet growing demands for quality and functionality. Furthermore, Aersulate® viscose fibers are sustainable and provide an animal-friendly alternative to down-based products, thereby promoting animal welfare."

Volker Schuster, Head of Research and Development at Outlast Technologies